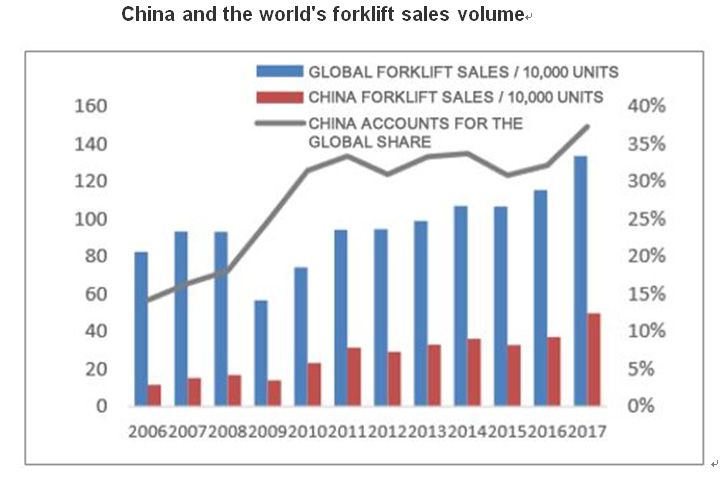

Although domestic forklift production starts later than foreign countries, Western technology is higher than domestic ones, but the product series is relatively comprehensive. Since the 1980s, through the introduction of TCM, Mitsubishi and Nissan (Nissan) technology, China's forklift design and manufacturing technology has developed rapidly. At present, the design technology of the whole machine is close to the international frontier level, but there is still a big gap in the design and manufacturing level of key components such as engines. Since the 1990s, there have been more than 250 forklift manufacturers around the world. The main countries are Germany, Japan, the United States, Bulgaria and Sweden, and Asia is mainly Japan, South Korea and China. According to statistics, the global sales of forklifts increased from 824,100 units in 2006 to 1,333,800 units in 2017, with an annual compound growth rate of 5%, which is one of the most complex mechanical equipment in the past decade. China's forklift sales volume has grown at a compound annual rate of 15%, and sales in the 18-year period are expected to exceed 580,000 units. In 2006, it was 111.6 million units, and in 2017, it was 496,700 units. It is estimated that the total sales volume in 2008 will exceed 580,000 units, and the annual compound growth rate will be 15%, which has achieved a huge leap in the industry.